Welcome! This manual details the 2013 Chevrolet Cruze, offering guidance on features, operation, maintenance, and safety—a key resource for all owners.

Purpose of the Manual

This 2013 Chevy Cruze Owner’s Manual serves as a comprehensive guide designed to familiarize you with your vehicle’s operation and features. It details everything from understanding dashboard symbols to performing routine maintenance, ensuring a safe and enjoyable driving experience. The manual aims to help you maximize the vehicle’s potential while adhering to Chevrolet’s recommended practices.

It provides crucial information regarding the vehicle’s systems, including electrical diagrams and safety features like the airbag and anti-lock braking systems. Furthermore, it outlines warranty details and offers troubleshooting advice for common issues. Authorized Chevrolet service centers are equipped to provide expert assistance, leveraging training and genuine parts. This manual is your first step towards responsible vehicle ownership and long-term reliability.

Vehicle Identification

Proper vehicle identification is crucial for service, warranty claims, and accurate parts ordering for your 2013 Chevy Cruze. This section details how to locate your vehicle’s unique identifiers. The Vehicle Identification Number (VIN) is a 17-character alphanumeric code, typically found on the driver’s side dashboard near the windshield, and on your vehicle registration and insurance documents.

Understanding the VIN allows Chevrolet and authorized service centers to access specific information about your vehicle’s build and configuration. The manual also explains locating other important identification plates containing information about the engine, transmission, and paint code. Maintaining accurate records of these identifiers ensures efficient service and support throughout your ownership experience.

Understanding Your Vehicle

Explore your Cruze! This section details the dashboard, instrument panel, and key features, helping you become familiar with its controls and systems.

Dashboard Symbols and Indicators

Decoding the Lights: Your 2013 Chevy Cruze’s dashboard utilizes a series of symbols and indicators to communicate vital information about the vehicle’s status. Understanding these lights is crucial for safe and informed driving. Illuminated symbols require immediate attention, potentially indicating a mechanical issue needing prompt service.

Key Indicators: Expect to see lights for engine function, brake system status, airbag deployment, and various fluid levels. Warning lights for low tire pressure, seatbelt reminders, and exterior lighting malfunctions are also common. Refer to the manual for specific color coding – red typically signifies a serious problem, yellow indicates a potential issue, and green or blue generally confirms a system is active.

Regular Checks: Familiarize yourself with the location and meaning of each symbol before driving. Ignoring a warning light could lead to more significant damage or compromise safety.

Instrument Panel Overview

Central Information Hub: The 2013 Chevy Cruze’s instrument panel provides a comprehensive display of essential vehicle data. Centrally located, the speedometer and tachometer clearly indicate speed and engine RPM. A multi-information display (MID) nestled between these gauges presents crucial metrics like fuel level, engine temperature, and trip information.

Key Displays: The MID is customizable, allowing drivers to cycle through various readouts, including average fuel economy, distance to empty, and outside temperature. Warning lights, as discussed previously, are prominently displayed to alert drivers to potential issues. The panel also incorporates indicators for turn signals, high beams, and cruise control activation.

Easy Navigation: Controls for the MID are typically located on the steering wheel, enabling convenient adjustment without diverting attention from the road.

Feature Highlights of the 2013 Cruze

Balanced Performance & Efficiency: The 2013 Chevy Cruze distinguishes itself with a commendable balance of reliability and fuel efficiency. Its 1.4L Turbo engine delivers adequate power while prioritizing economical operation, making it suitable for daily commutes.

Comfort & Convenience: Inside, the Cruze offers a comfortable cabin with standard features like air conditioning and a sound system. Available upgrades included features like Bluetooth connectivity and a USB port for enhanced entertainment and convenience.

Safety First: Safety is a key highlight, featuring standard anti-lock brakes and a comprehensive airbag system. The available stability control system further enhances driver control and safety in challenging conditions, providing peace of mind on every journey.

Operating Your Vehicle

Essential Guidance: This section provides detailed instructions for safely starting, driving, and maximizing fuel efficiency within your 2013 Chevrolet Cruze.

Starting and Stopping the Engine

Starting Your Cruze: Ensure the parking brake is engaged and the transmission is in Park (P) or Neutral (N). Insert the key into the ignition and turn it to the ‘Start’ position, releasing once the engine starts. For vehicles with a keyless ignition system, depress the brake pedal and press the ‘Start/Stop’ button.

Engine Operation: Allow the engine to idle for a short period, especially in cold weather, to ensure proper lubrication. Monitor the instrument panel for any warning lights.

Stopping the Engine: To shut down, gently apply the brakes, shift the transmission into Park (P), and turn the ignition key to the ‘Off’ position, or press the ‘Start/Stop’ button. Remove the key to prevent accidental operation. Always ensure the vehicle is completely stopped before shifting into Park.

Driving Modes and Fuel Efficiency

The 2013 Chevy Cruze is designed for optimal fuel efficiency. Driving habits significantly impact MPG. Avoid aggressive acceleration and hard braking to maximize fuel economy. Maintaining consistent speeds on the highway also helps.

While the Cruze doesn’t feature selectable driving modes like some modern vehicles, its engine and transmission are tuned for balance. Utilizing cruise control on long drives can contribute to better fuel consumption.

Regular maintenance, including tire inflation and fluid checks, is crucial for maintaining peak efficiency. A well-maintained engine operates more effectively, reducing fuel waste. Consider lighter loads and minimizing air conditioning use for further improvements.

Using the Gearshift and Transmission

The 2013 Chevy Cruze primarily features a six-speed automatic transmission, offering smooth and efficient gear changes. The gear selector positions include Park (P), Reverse (R), Neutral (N), Drive (D), and a manual shift mode (M).

To shift gears, firmly press the brake pedal and move the selector to the desired position. For manual control, shift up or down using the selector lever. The transmission automatically prevents shifting into a gear that could damage the vehicle.

Avoid shifting while the vehicle is under heavy acceleration. Proper gear selection optimizes performance and fuel economy. Regularly check transmission fluid levels to ensure smooth operation and longevity.

Maintenance and Care

Protect your investment! This section outlines essential maintenance—fluid checks, tire care, and a recommended schedule—to keep your 2013 Cruze running smoothly.

Recommended Maintenance Schedule

Maintaining peak performance for your 2013 Chevy Cruze requires adherence to a specific maintenance schedule. Every 7,500 miles (or six months, whichever comes first), oil and filter changes are crucial. Inspect tire pressure and tread depth monthly, and rotate tires every 8,000 miles to ensure even wear.

At 30,000 miles, replace the engine air filter and cabin air filter. Inspect brake pads, rotors, and fluid levels. A more comprehensive inspection should occur at 60,000 miles, including coolant replacement, transmission fluid check, and spark plug inspection. Following this schedule, detailed in your owner’s manual, will maximize your Cruze’s longevity and reliability, ensuring safe and efficient operation for years to come. Authorized Chevrolet service centers offer expert maintenance.

Fluid Checks and Replacements

Regular fluid level checks are vital for your 2013 Chevy Cruze’s health. Inspect engine oil weekly, adding as needed to maintain the proper level. Check coolant levels in the reservoir when the engine is cold, and top off with the correct coolant type. Brake fluid should be inspected regularly for contamination and replaced every two years, or as indicated.

Power steering fluid levels should also be monitored. Transmission fluid condition is critical; a flush is recommended every 60,000 miles. Windshield washer fluid should be filled frequently. Using the correct fluids, as specified in your owner’s manual, is essential for optimal performance and preventing damage to your vehicle’s systems.

Tire Information and Maintenance

Proper tire care significantly impacts your 2013 Chevy Cruze’s safety and fuel efficiency. Regularly check tire pressure – including the spare – and inflate to the recommended PSI found on the tire placard (usually located on the driver’s side doorjamb). Inspect tires for wear and damage, such as cuts or bulges;

Rotate tires every 7,500 miles to ensure even wear. Tire tread depth is crucial; replace tires when they reach the wear bars. Use tires of the same size and type on each axle. Adhering to these guidelines will maximize tire life, improve handling, and contribute to a safer driving experience for your Cruze.

Safety Features

Your 2013 Cruze incorporates vital safety systems like airbags, ABS, and stability control, designed to protect you and passengers during driving conditions.

Airbag System

The 2013 Chevy Cruze is equipped with an advanced airbag system designed to provide crucial protection during certain collision events. This system includes front and side airbags for both front occupants, as well as side curtain airbags protecting those in the outboard rear seating positions.

Airbags are supplemental restraints and work in conjunction with seat belts – they are not a replacement for them. Always ensure all occupants are properly restrained. The system is designed to deploy in moderate to severe frontal and side impacts. Sensors detect the severity of the impact and deploy airbags accordingly.

Important Safety Notes: Never place rear-facing child seats in the front passenger seat if the airbag cannot be deactivated. Improperly installed or modified airbags can be dangerous. Refer to the full owner’s manual for detailed information regarding the airbag system and its limitations.

Anti-lock Braking System (ABS)

Your 2013 Chevy Cruze features an Anti-lock Braking System (ABS) designed to help maintain steering control during hard braking situations and reduce stopping distances on most surfaces. ABS prevents wheel lockup, allowing you to steer around obstacles while braking.

When ABS activates, you may feel a pulsing sensation in the brake pedal and hear a clicking noise – this is normal and indicates the system is working correctly. Maintain firm, steady pressure on the brake pedal during ABS activation; do not pump the brakes.

Important Considerations: ABS does not eliminate the need for careful driving. Road conditions and tire condition still significantly impact braking performance. Familiarize yourself with how ABS functions to ensure optimal use in emergency braking scenarios. Consult the owner’s manual for detailed information.

Stability Control System

The 2013 Chevy Cruze is equipped with a Stability Control System (StabiliTrak) designed to help maintain directional control during challenging driving conditions, such as slippery roads or sudden maneuvers. This system selectively applies brakes to individual wheels to help steer the vehicle where you intend to go.

You’ll notice a flashing indicator light on the instrument panel when the system is actively working. It’s crucial to remember that StabiliTrak is a supplement to safe driving practices, not a replacement for them. Avoid aggressive driving and always adjust your speed to road conditions.

Important Note: While effective, StabiliTrak has limitations. It cannot overcome the laws of physics, and factors like tire condition and vehicle load impact its performance. Refer to the owner’s manual for a comprehensive understanding of the system’s capabilities.

Electrical System

Explore the 2013 Cruze’s electrical components, including battery details, jump-starting procedures, fuse box locations, and a general overview of wiring diagrams.

Battery Information and Jump Starting

Your vehicle’s battery is a crucial component of the electrical system, providing power to start the engine and operate electrical accessories. Understanding its specifications and proper maintenance is essential for reliable performance. The 2013 Chevy Cruze utilizes a specific battery type; consult your manual for exact details.

Jump starting a discharged battery requires careful adherence to safety precautions. Always wear eye protection and ensure the vehicles do not touch. Connect the jumper cables in the correct sequence – positive to positive, negative to a grounded metal surface on the disabled vehicle – to avoid sparks and potential damage. Incorrect procedures can harm the electrical systems of both vehicles. Refer to the manual for a detailed, step-by-step guide to safe jump-starting.

Fuse Box Locations and Diagrams

Protecting the electrical circuits in your 2013 Chevy Cruze are fuses, designed to blow and interrupt the flow of electricity in case of an overload. Knowing the location of these fuse boxes is vital for addressing electrical issues. Your Cruze has at least two fuse box locations: typically one inside the passenger compartment, often under the dashboard, and another within the engine compartment.

Detailed fuse diagrams are provided in the owner’s manual, illustrating the specific function of each fuse. Before replacing a blown fuse, identify the circuit it protects. Always use a fuse with the correct amperage rating; using a higher amperage fuse can cause serious damage to the electrical system. The manual’s diagrams are essential for accurate identification and safe fuse replacement.

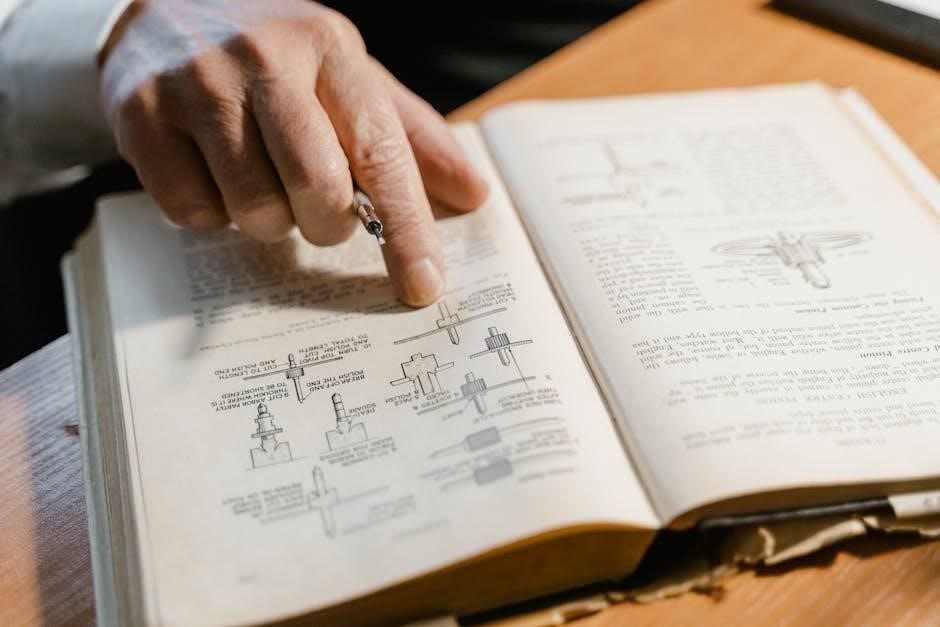

Wiring Diagrams Overview

Understanding the electrical system of your 2013 Chevy Cruze requires access to comprehensive wiring diagrams. These diagrams illustrate the pathways of electrical circuits, showing how components are interconnected. The owner’s manual, and more detailed repair manuals, contain these crucial schematics. They depict wire colors, connector locations, and component pinouts, essential for diagnosing and repairing electrical faults.

These diagrams cover various systems, including the air conditioning, anti-lock brakes, and the entire engine management system. While complex, they are invaluable for anyone attempting electrical repairs. Proper interpretation requires a basic understanding of electrical principles and symbols. Always disconnect the battery before working on any electrical component, and consult a qualified technician if you are unsure about any procedure.

Troubleshooting

Facing issues? This section provides solutions for common problems, explains warning lights, and guides you through diagnosing potential concerns with your 2013 Cruze.

Common Issues and Solutions

Addressing typical concerns, the 2013 Chevy Cruze sometimes experiences issues with the cooling system, potentially leading to overheating. Regularly check coolant levels and inspect for leaks. Another frequent problem involves the turbocharger, manifesting as reduced engine power; professional diagnosis is crucial. Electrical glitches, like malfunctioning sensors, can trigger warning lights – a scan tool helps pinpoint the source.

Furthermore, some owners report issues with the power windows and door locks. Inspecting fuses and wiring connections is a good starting point. For persistent problems, consult a qualified technician. Remember, attempting complex repairs without proper knowledge can exacerbate the issue. Prioritize safety and seek professional assistance when needed to maintain your Cruze’s reliability.

Warning Lights and Their Meanings

Understanding dashboard illumination is vital for safe operation. A solid “Check Engine” light indicates a potential engine or emissions system issue – schedule a diagnostic check. The “ABS” light signals a problem with the anti-lock braking system, potentially affecting braking performance. A flashing “Tire Pressure” light means low tire pressure; inflate tires promptly.

The “Battery” light warns of charging system problems, while a low “Fuel” light indicates dwindling fuel reserves. An illuminated “Airbag” light suggests a fault in the airbag system, requiring immediate attention. Ignoring warning lights can lead to more significant damage. Consult your owner’s manual for a comprehensive list and appropriate actions for each indicator.

Warranty Information

Chevrolet provides comprehensive coverage for your 2013 Cruze, detailing specific terms, durations, and exclusions—review the details for peace of mind.

Chevrolet Warranty Details

Your 2013 Chevy Cruze is protected by Chevrolet’s commitment to quality, encompassing several warranty provisions. The bumper-to-bumper limited warranty typically covers defects in materials or workmanship for 3 years/36,000 miles, whichever comes first. Powertrain coverage, safeguarding the engine, transmission, and drive systems, extends to 5 years/100,000 miles.

Additionally, corrosion protection is offered for 6 years/100,000 miles. Specific warranty details, including what’s covered and excluded, are outlined in the official warranty booklet provided with your vehicle. It’s crucial to retain this document and adhere to the recommended maintenance schedule to maintain warranty validity. Authorized Chevrolet service centers are equipped to handle warranty claims efficiently.